Product introduction:

The Ultra-fine enameled rectuangular copper wire is ≤ 6mm². It is made by rectangular copper wire coated with high temperature insulating varnish. This product can meet the customer's different ways of winding, and the product parameters include insulation species, temperature index, conductor thickness and width. Precision enameled flat wire widely used in electronic transformers, power supplies, solar energy, wireless chargers, automotive electronics, switches, mobile phones and other high-tech precision products.

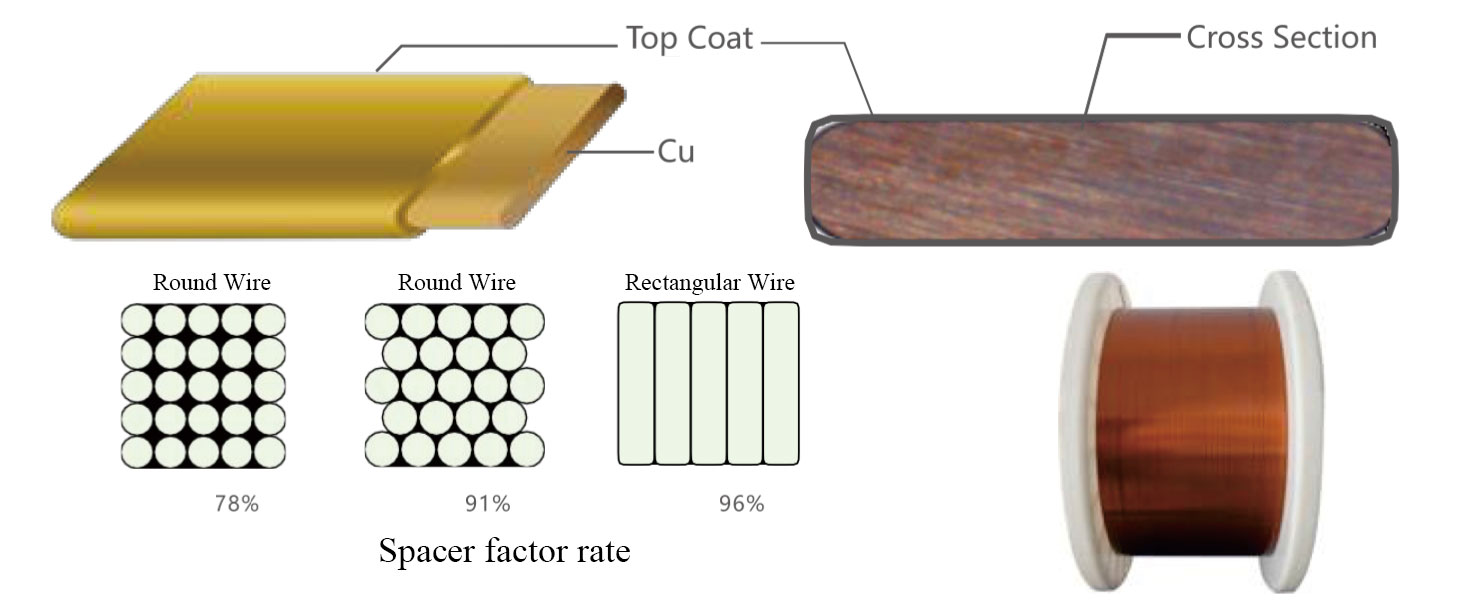

Advantages of the precision enameled flat wire:

1.In the same winding space, it can make the coil spacer factor rate up to 96%, thereby reducing the resistance, to obtain greater current.

2.The use of precision enameled flat wire has a larger surface area, better thermal performance. It can effectively improve the skin effect and reduce high-frequency current consumption.

3.Nowadays, the exterior design of electronic, electrical, digital, automotive and other products toward the development of "light, thin, short, small". In the same winding space, precision enameled flat wire can make higher coil spacer factor rate, and meet the requirement of the flattening, light weight, low power consumption and high performance.

When using the precision enameled flat wire, the coil electromagnetic effect is better. When the coil is withstanding high-current work, it will be less vibration and low noise.

Magnet wire has rich variety and complete range of specifications,and we can meet customer purchasing requirements.

1.Magnet wire has rich variety and complete range of specifications,and we can meet customer purchasing requirements.

2.We imported the first-class enameled flat wire equipment,the product performance’s consistency is stable;

3.The precision enameled flat wire has a great adhesion.

4.We are the world's leading electrical manufacturing enterprises long-term and stable partners

Enameled wire performance paraeters table

| Product Name | UEW155 | UEW180 | EI/AIW200 | AIW/220 | PIW240 |

| Standrad | IEC 60317-20 MW 79C JIS 3202 | IEC 60317-51 MW 82C JIS 3202 | IEC 60317-13 MW 35C,73C JIS 3202 | IEC 60317-26 MW 81C JIS 3202 | IEC 60317-46 MW 16C |

| Temperature | 155℃ | 180℃ | 200℃ | 220℃ | 240℃ |

| Enamel Base Coat | Polyurethane | Polyurethane | Polyamide-imide | Polyamide-imide | Polyimide |

| Enamel Top Coat | Polyester-imide | ||||

Breakdown temperature | ≥ 200° C | ≥ 230° C | ≥ 320° C | ≥ 350° C | ≥ 400° C |

230° C | 260° C | 380° C | 410° C | 450° C | |

Thermal shock temperature | ≥ 175° C | ≥ 200° C | ≥ 220° C | ≥ 240° C | ≥ 240° C |

| 180℃ | 200℃ | 240℃ | 280℃ | 300℃ | |

Welding temperature | 380° C | 390° C | Can not be welded | Can not be welded | Can not be welded |

370° C | 380° C | ||||

Tensile strength | 260MPa | 265MPa | 270MPa | 280MPa | 270MPa |

| Breakdown | 100 V/µm | 100 V/µm | 90 V/µm | 100 V/µm | 90 V/µm |

Breakdown voltage decline rate after the chemical standard solvent treatment | 5% | 0% | 0% | 5% | 0% |

| Production Range (Thickness a,Width b) | a: 0.080-1.00mm | a: 0.080-1.00mm | a: 0.080-1.20mm | a: 0.080-1.20mm | a: 0.080-1.20mm |

| b: 0.800-6.00mm | b: 0.800-6.00mm | b: 0.800-8.00mm | b: 0.800-8.00mm | b: 0.800-8.00mm | |

| Performance | ●excellent weldability ●high heat | ●directly welded in 380 ℃ ●high heat resistance | ●high heat resistance ●high mechanical properties | ●high heat resistance ●excellent chemical resistance | ●excellent heat resistance ●excellent chemical resistance ●excellent radiation resistance |

| Application | ● filter ●transformers ●solenoids | ●filter ●transformers ●solenoids ●automotive coils | ●motors | ●small motors ●sransformers ●solenoids ●automotive sensors | ●military ●space applications |