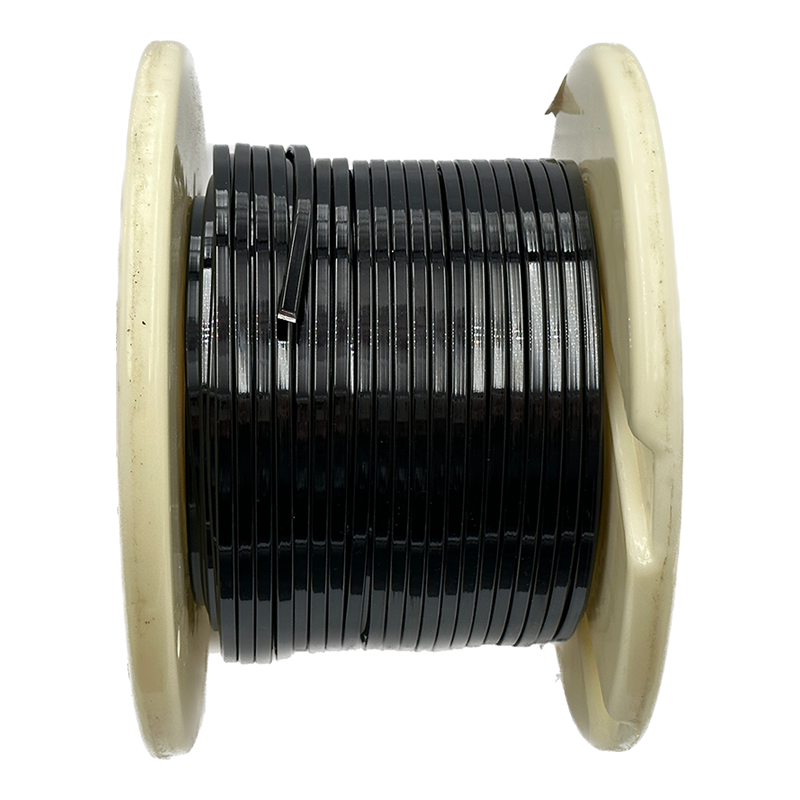

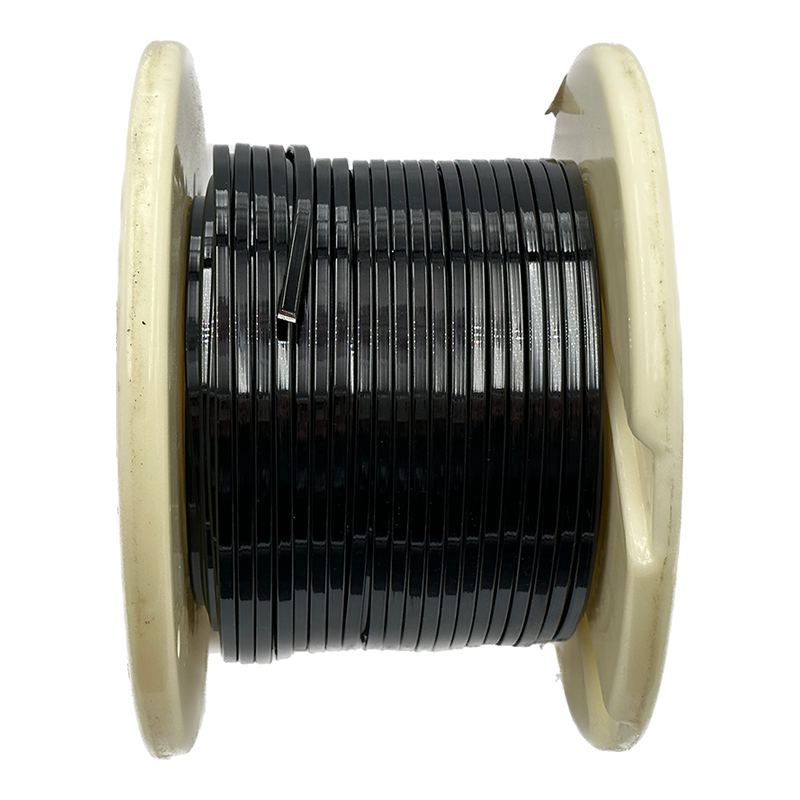

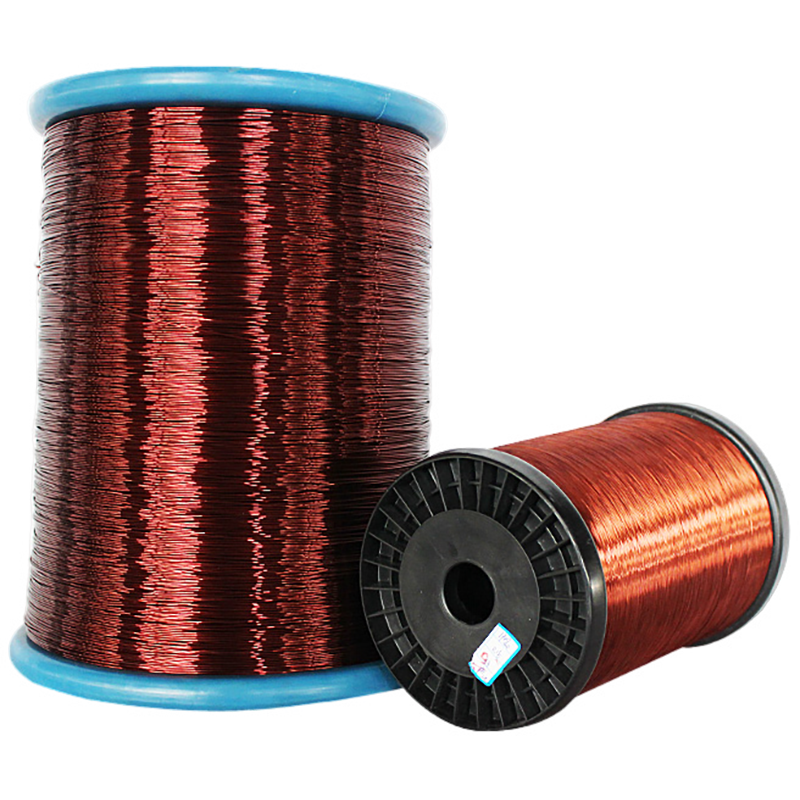

Enameled Square Winding Wire is mainly used as an electrical conductor wherever coils are in motion. It's available size in diameters from 1.0mm to 6.0mm(SWG2-15,AWG4-13) with different insulation, such as Polyurethane, Polyester, Polyesterimide, Polyimide etc.. The enamelled Square magnet wire reach to production standards: IEC60317,NEMA MW1000/JIS C3202.

1.120 degree flat enamelled wire for oil-immersed transformer

2.130, 155, 180 degree flat enamelled wire are widely used in all kinds of magnet coil

3. 200 degree flat enamelled wire works constantly in high temperature

4. 240 degree flat enamelled wire for magnet coils of aviation, military and marine application

Square wire thickness/width: 1.0-6.0mm

Width/ thickness ratio: 1.0<w/t<2.0

| Product Name | QZ-130 PEW130 | QZGB-155 PEW155 | QZ-180 EIW180 | Q(ZY/XY)-200 AI/EIW200 | QY -240 AIW240 |

| Standard | IEC60317-16 GB/T7095.7 | IEC60317-16 GB/T7095.3 | IEC60317-28 GB/T7095.4 | MW 36 IEC60317–29 GB/T7095.6 | MW 20 IEC60317-47 GB/T7095.5 |

| Thermal Class | 130℃ | 155℃ | 180℃ | 200℃ | 240℃ |

| Enamel Base Coat | Polyester | Modified Polyester | Polyester-Imide | Polyester-Imide | Polyimide |

| Enamel Top Coat | - | Polyamide-Imide | |||

| Cross Section Range | 2 – 36mm2 | 2 – 36mm2 | 2 – 36mm2 | 2 – 36mm2 | 2 – 36mm2 |

| Range of insulation thickness | IEC 60317-0-2 G1,0.06-0.11mm G2,0.12-0.17mm | IEC 60317-0-2 G1,0.06-0.11mm G2,0.12-0.17mm | IEC 60317-0-2 G1,0.06-0.11mm G2,0.12-0.17mm | IEC 60317-0-2 G1,0.06-0.11mm G2,0.12-0.17mm | IEC 60317-0-2 G1,0.06-0.11mm G2,0.12-0.17mm |

| Performance | ●excellent bending property ●high flexibility of the enamel ●good resistance to abrasion ●high mechanical property | ●higher thermal property ●excellent bending property ●high flexibility of the enamel ●good resistance to abrasion ●high mechanical property | ●higher thermal property ●suitable for windings that are subjected to constantly high temperature and mechanical stress ● good chemical resistance | ●excellent thermal resistance ●suitable for windings that are subjected to constantly high temperature and mechanical stress ●good chemical resistance ●good resistance to refrigerant and freon | ●excellent thermal resistance suitable for any electric equipments that are constantly exposed to high working temperature ●outstanding mechanical and chemical property ●good performance against radiation |

| Application | ●dry & oil-immersed transformer ●electrical equipment | ●dry & oil-immersed transformer ●electrical equipment | ●winding of high and low voltage DC/AC motor ●magnet coil ●dry & oil-immersed transformer | ●winding of high and low voltage DC/AC motor ●magnet coil ●dry & oil-immersed transformer ●automobile coil ●train coil | ●winding with service temperature up to 220°C ●motor and generator for aviation and marine application ●nuclear industry ●winding requiring high reliability |

| Heat shock | 155℃ | 175℃ | 200℃ | 220℃ | 260℃ |