Continuously Transposed Cable(CTC) is a kind of winding wire made of a certain numbers of enameled rectangular wires arranged in two columns in sequence by special technology,and wrapped by special insulating materials.

It is mainly used in the winding of large oil immersed power transformers,reactors and large capacity dry-type transformers.By applying transposed wires to transformers,the space utilization ratio of winding is improved,the volume and the cost is reduced.

What’s more,the additional loss of circulation and eddy current loss caused by leakage magnetic field are reduced.At the same time,it has the advantages of improving the mechanical strength of the winding and saving the winding time etc.

CTC is the important material for transformer winding.It has the advantage of well using of space,low eddy current loss,high mechanical strength and less time of coil winding.

PRODUCT SCOPE

Polyvinylacetal enameled CTC with paper insulation

Polyvinyl self-adhesive acetal enameled CTC with paper insulation

Polyvinyl self-adhesive semi-hard acetal enameled CTC with paper insulation

Polyvinylacetal enameled CTC with special binding

Composite CTC with step

Composite CTC with screen wire inside

Polyester-imide enameled CTC

Polyviny alcohol enameled CTC with PET film insulation

PRODUCTION RANGE

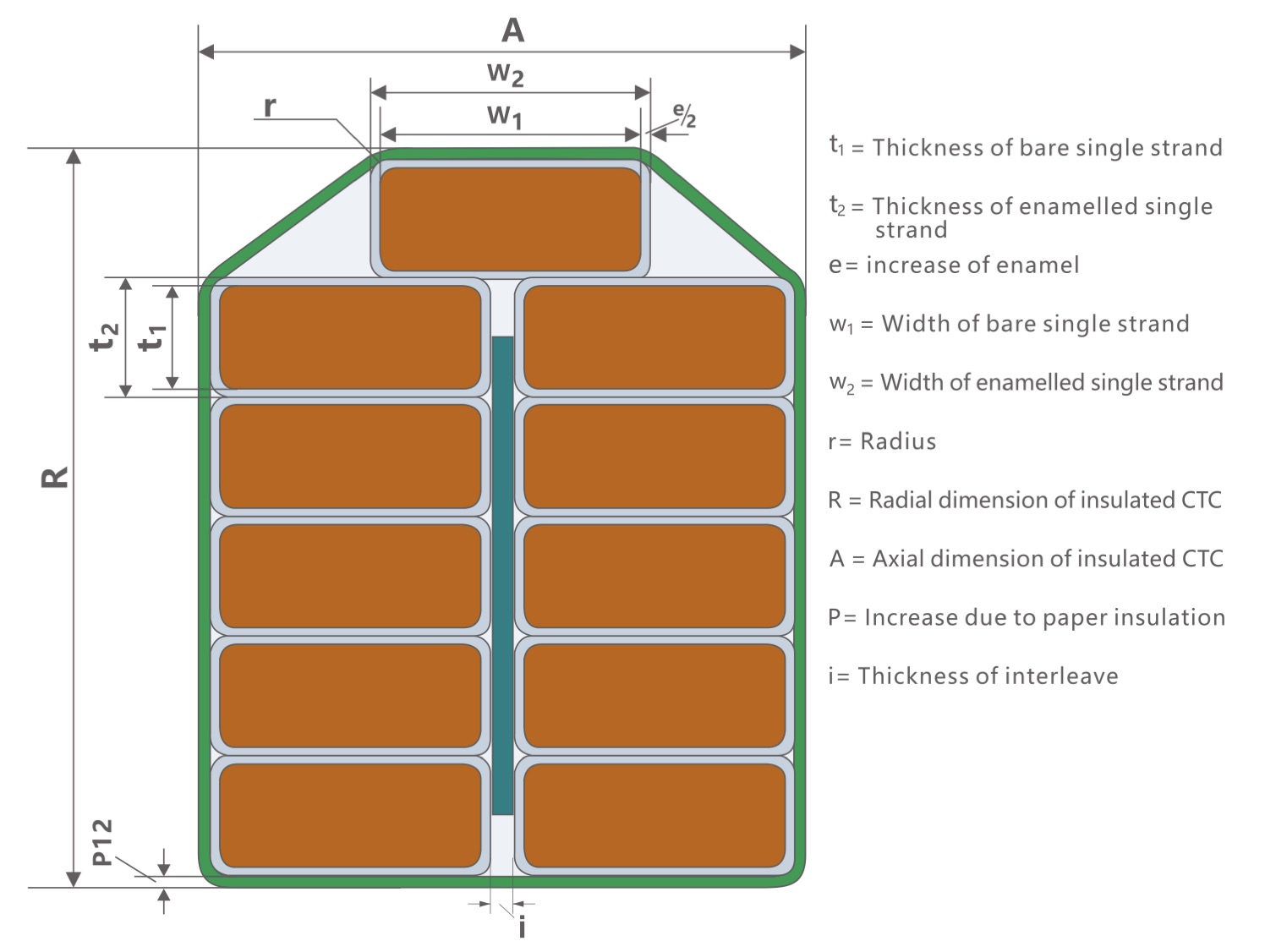

| Continuously Transposed Conductors (CTC) | |

| CTC strips | 5-80(odd or even) |

| Max overall dimension | Height: 120mm (Tolerance±0.05mm) |

| Width: 26mm (Tolerance±0.05mm) | |

| Single Conductor | Thickness a: 0.90-3.15mm(Tolerance±0.01mm) |

| Width b: 2.50-13.00mm(Tolerance±0.01mm) | |

| Width/thickness ratio of single conductor | 2.0<b/a<9.0 |

| Thickness of enamel insulation | 0.08-0.12mm |

| Thickness of bonding epoxy resin | 0.03-0.05mm |

| If the specifications is out of the above range,please contact us. | |

Continuously Transposed Cable(CTC) Application for:

Large oil immersed power transformers

Reactors

Large capacity dry-type transformers